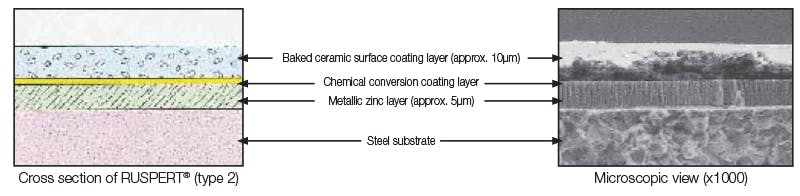

It consists of three layers: the 1st layer: a metallic zinc layer, the 2nd layer: a high-grade anticorrosion chemical conversion film, and a 3rd outer layer; baked ceramic surface coating.

The distinguishing feature of RUSPERT® is the tight joining of the baked ceramic surface coating and the chemical conversion film. These layers are bonded together through chemical reactions, and this unique method of combining layers results in a rigid combination of the coating films.

RUSPERT® treatment does not attribute its anti-corrosion properties to merely a single material, but the synergy of these three layers, which combined have superb corrosion resistant qualities.

RUSPERT® Patent No. 1526310 and 1570203.

| Coating Layers | Corrosion Resistance Mechanism | |

|---|---|---|

| 1st layer | Metallic zinc layer | The steel/iron substrate is protected from corrosion by the self sacrificial galvanic effect of the zinc coating. |

| 2nd layer | Chemical conversion coating layer | Corrosion resistant performance is improved as the chemical conversion inactivates the zinc plated surface and creates a tight adhesion between the chemically converted layer and the paint layer. |

| 3rd layer | Baked ceramic surface coating layer | Corrosive elements are intercepted by the strong paint film made of ceramic materials. |

| Test Items | RUSPERT | Zinc electroplating (Coloured Chromate) | Hot Dip Galvanizing |

|---|---|---|---|

| Before Tests |  |

|

|

| Salt spray tests after 1,000 hours Test method: 5% concentrated salt mist continuously sprayed in accordance with JIS Z 2371 standard. |

|

|

|

| Combined corrosion test after 200 cycles Test method: repeat a series of cycles, each cycle consists of 2 hours of salt spraying, 4 hours of drying at 60ºC (140ºF) and 2 hours of exposure to humidity of 95% R.H. at 50ºC (122ºF) in accordance with JASO M609-9 1 standard. |

|

|

|

| Cass test after 10 cycles Test method: repeat series of cycles, each cycle consists of 16 hours of exposure and 6 hours of non-exposure to an acetic acid solution of 5% concentration with it pH adjusted between 3.0 and 3.1. |

|

|

|

| Sulfur dioxide gas corrosion test after 15 cycles Test method: repeat a series of cycles, each cycle consists of 8 hours of exposure to a condensation of gas under 9.8R.H. at 40ºC (104ºF) after supplying sulfur dioxide gas (SO2) of 2.0 ltr to a tightly sealed chamber of 300 ltr & 16 hours of drying at 75% R.H. |

|

|

|

Note: the corrosion resistance of Ruspert® will depend on a range of factors including the environment. Anzor does not provide any warranty regarding Ruspert’s® corrosion resistance.

BUMAX® DX 129: The World's Strongest Stainless Steel Bolts

Build without delays with Anzor Quick Drill Screws for timber construction.

Lindapter Girder Clamps: Safe and Secure Connections

To receive useful info and product updates add your details below